There are many dangers when extracting, transporting and refining oil & gas or any other dangerous materials. Two of the major ones are fires and explosions. It can potentially harm people, destroy installations, as well as create environmental catastrophes. An efficient way to lower the possible damages is to protect the equipments that control the flow of hazardous materials. Appropriate fire protection for the valves and especially for the actuators is critical in case of emergency to maintain control over the automation process and contain an incident.

Nowadays, most actuator manufacturers can supply a fire protection solution tailored to their own device. There are three kind of passive fire protections for actuators available on the market:

- Intumescent Paint

- Rigid Enclosures

- Flexible Thermal Blanket

These fire protection solutions can be used for new actuators and also retro-fitted on existing valve automation installations. What varies between the different fire proofing solutions is the duration of protection against a certain type of heat exposure.

Intumescent Paint for Actuators

This special coating can protect the device from fire up to 2000°F and for more than 30 minutes. How does it work? Upon sensing heat, a chemical reaction occurs and several layer of protective char (carbon) are created. This type of retardant materials also adds chemicals which cause swelling up behind the protective char layer.

Usually, metal rejects around 20% of the heat of a fire, with the intumescent coating on the actuators, it keeps away up to 90% of the heat. This passive fire protection solution is a really effective heat barrier. It doesn’t not require any specific maintenance, nor suffers from the weather. The coating is a paint job so it still allows full access to the actuator enclosure and doesn’t limit the capacities of the device. However, it is only available for new actuators.

Rigid Enclosures for Actuators

Perfect for retro-fit applications, the actuator and eventually the gearbox are encased in a large enclosure. This enclosure can be made of various high thermal performance materials. Most of the time, the design will include a removable panel, sort of door, to allow quick and easy access the actuator inside.

Perfect for retro-fit applications, the actuator and eventually the gearbox are encased in a large enclosure. This enclosure can be made of various high thermal performance materials. Most of the time, the design will include a removable panel, sort of door, to allow quick and easy access the actuator inside.

These rigid enclosures can resist to both explosions and flames up to a temperature of 2,200°F and for more than 2 hours depending on the construction materials and the nature of the fire.

Finally, a rigid enclosure is really useful on a process line equipped with several automated valves in a close space, as one large rigid enclosure can protect quite a few devices.

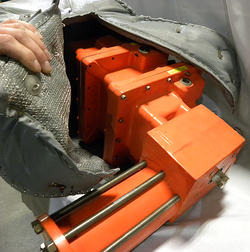

Flexible Thermal Blanket for Actuators

This compact fire protection solution works for both new and existing actuators, and for other critical equipment of a plant as well.

It is a custom fit solution with very low maintenance. Easy to install, remove and reinstall it provides easy serviceability of the actuator inside. Moreover, flexible thermal blankets are tough, lightweight, weatherproof and very cost effective.

It is a custom fit solution with very low maintenance. Easy to install, remove and reinstall it provides easy serviceability of the actuator inside. Moreover, flexible thermal blankets are tough, lightweight, weatherproof and very cost effective.

A typical application for flexible thermal blanket on an actuator is damper automation in railroad tunnels, or underground passenger platforms. The combination of a spring return electric actuator with a flexible thermal blanket is designed and tested to operate successfully in extreme temperatures, meeting or exceeding minimum requirements (2 hours at 550°F without failure) for tunnel applications around the world, for countries such as USA, Canada, UK, France, Switzerland, Netherlands, Japan and many more...