What’s a Thermal Actuator?

Actuators are simply devices used to transform energy into motion. A thermal actuator is a type of non-electric motor made of components such as a piston and a thermal sensitive material capable of producing linear motion in response to temperature changes.

The use of Thermal Actuators

Opposite others devices, a thermal actuator doesn’t require outside power source to produce motion. In a thermal actuator system, temperature changes can be used to perform pre-defined tasks such as release latches, operate switches and open or close valves. These devices are very sensitive and can be used for applications that require actuation even at very slight temperature changes. They can be used for many applications; the aerospace, automotive, agricultural industries, solar and HVAC to name just a few...

How is this possible?

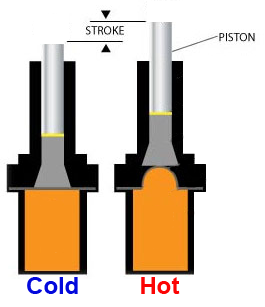

The thermal-sensitive materials used in a thermal actuator respond to fluctuations in temperature, causing the actuator's piston component to move. These materials are engineered to expand as temperatures increase, driving a piston out of the actuator. When a thermal actuator is exposed to drops in temperature, the thermal-sensitive materials inside contract, allowing the piston to retract.

contract, allowing the piston to retract.

What’s the stroke of a Thermal Actuator?

Stroke refers to the distance a piston travels outward from a linear actuator. Many of the more common thermal actuators feature pistons that can extend between 0.015 inches (0.381 millimeters) and 0.500 inches (12.7 millimeters). Most thermal actuators are made to react to temperatures anywhere between 86 degrees Fahrenheit (30 degrees Celsius) and 572 degrees Fahrenheit (300 degrees Celsius).

Production

Manufacturers produce thermal actuators in a wide range of sizes and options, making them ideal for many different applications. Many thermal actuators are designed for use in pressurized or vacuum, gas, or liquid environments. They can be built out of durable, rugged materials such as aluminum, brass or stainless steel and feature custom mounting configurations. Thermal actuators are easily machined and can be designed to feature any thread type or valve end. A good quality thermal actuator should be resistant to shock and vibration.

Concrete applications

In the aerospace industry, thermal actuators are used in safety shut-off processes, fuel temperature control and engine lubrication systems. This type of actuator is often used in the agricultural industry in livestock watering systems for freeze protection and in automatic greenhouse ventilation structures. The automotive industry utilizes thermal actuators in transmission cooler, thermostat and oil temperature regulation applications.