-

Featured Product

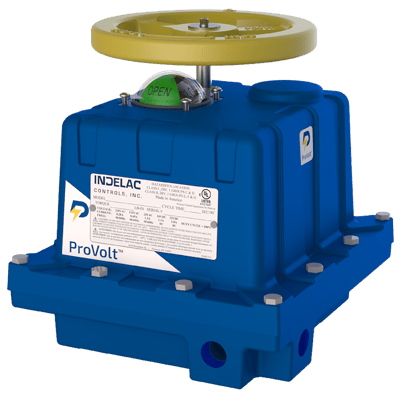

Featured ProductProVolt™

The ProVolt™ Series Universal Voltage Actuator is a quarter turn Rotary Actuator that will work with all voltage inputs. With the flip of an internal switch on the board, these actuators can accept any of the following input voltages: 115vac, 230vac, 24vac, 24vdc or 12vdc. No more ordering or stocking separate voltage actuators!

Learn More -

Featured Product

Featured ProductNEMA 6P Submersible Actuator

ICI’s M series NEMA 6P enclosure is designed for submersion in freshwater, to depths no greater than 6 feet, and for prolonged periods of time not exceeding 3 months (90 days).

Learn More -

Featured Product

Featured ProductK Series

The K Series is designed to automate quarter turn equipment requiring 5,000 to 27,300 In-Lbs of torque. It is equipped standard with a combination of spur gear / worm gear drive train meeting AWWA standards. With NEMA 4 and NEMA 7 enclosures, the K series also offers eight voltage options.

Learn More

- Oil & Gas

Industry Focus: Oil & Gas

Actuators are vital in every step of the oil and gas industry, whether for drilling, transport, processing or storage. Indelac actuators meet the challenging safety requirements of this market segment and comply with the increasing market demands for explosion protection certificates.

Learn More - Food and Beverage

Industry Focus: Food and Beverage

Actuators that come into direct contact with food are required to meet strict sanitary requirements. Indelac’s Safe & Secure series electric actuators are available with a food-grade epoxy coating and stainless steel components for washdown applications.

Learn More - Power Generation

Industry Focus: Power Generation

Indelac’s electric actuators successfully control flow of water and steam in power plant control systems. When used in power plants, our actuators satisfy the highest demands for control accuracy, reliability and safety, and can be adapted to any mounting position required.

Learn More - Valve Automation

Industry Focus: Valve Automation

Indelac provides full automation packages that are custom-built to solve our customers' specifications and unique challenges. Our team works closely with our customers to provide assistance and offer quality products that meet the most demanding project requirements.

Learn More - Water & Wastewater

Industry Focus: Water & Wastewater

Actuators used in water and wastewater management have to withstand enormous loads, high water pressures and extreme temperatures and weather conditions. Indelac’s electric actuators have earned an excellent reputation for the water treatment industry by offering easy installation, cost-effective solutions and more.

Learn More

Indelac Controls is a family-owned business that operates on values, quality, and leadership.

Family Owned

We take pride in providing uncompromised quality, backed by good people for over 30 years.

American Made

Building the best, competitively priced, American made electric actuators in Florence, Kentucky.

Energy Efficient

Committed to a sustainable future, we are always working towards lean production and energy efficiency.